TPE/TPS HR series- SBS

The HR series belongs to the SBS(STYRENE- BUTADIENE-STYRENE BLOCK COPOLYMER) non-hydrogenated grade of materials. The HR series involving applications of footwear, mainly for abrasion resistance, softness, tear strength and other requirements. For example, a pair of comfortable shoes needs to be highly abrasion resistant, have a good grip along with other functions and provide a protective heel and a comfortable insole that breathes.

This series is used in a wide range of shoes, including casual shoes, slippers and sport shoes. The HR series has adhesive properties and is thus able to work closely with other materials; it provides the functions for any shoes those basic requirements are wear-resistant and tough. Therefore, a good material made of elastic in scope of shoes, makes moving easier, that feels soft on the skin and comfortable for the legs to relieve fatigue!

Furthermore, it can be adapted for particular performances, for instance, with the excellent formula of thermoplastic elastomer material (TPE / TPS) and rubber resin blends, it favorably fulfills customers' special requirements for shoes!

Our HR series is used fairly extensively in shoe materials, for both the appearance and functionality of shoe accessories, heels, soles and insoles are mostly being with satisfied!

※Suitable for most of the thermoplastic processing methods, such as injection molding, extrusion molding and so on.

This material complies with EU RoHS regulations, Polynuclear Aromatic Hydrocarbons (PAHs), REACH SVHC (Substances of Very High Concern ), PFOS / PFOA and other safety tests.

Softnes

Dust resistant

Be glued

- Hardness : SHORE 5A ~ 60D

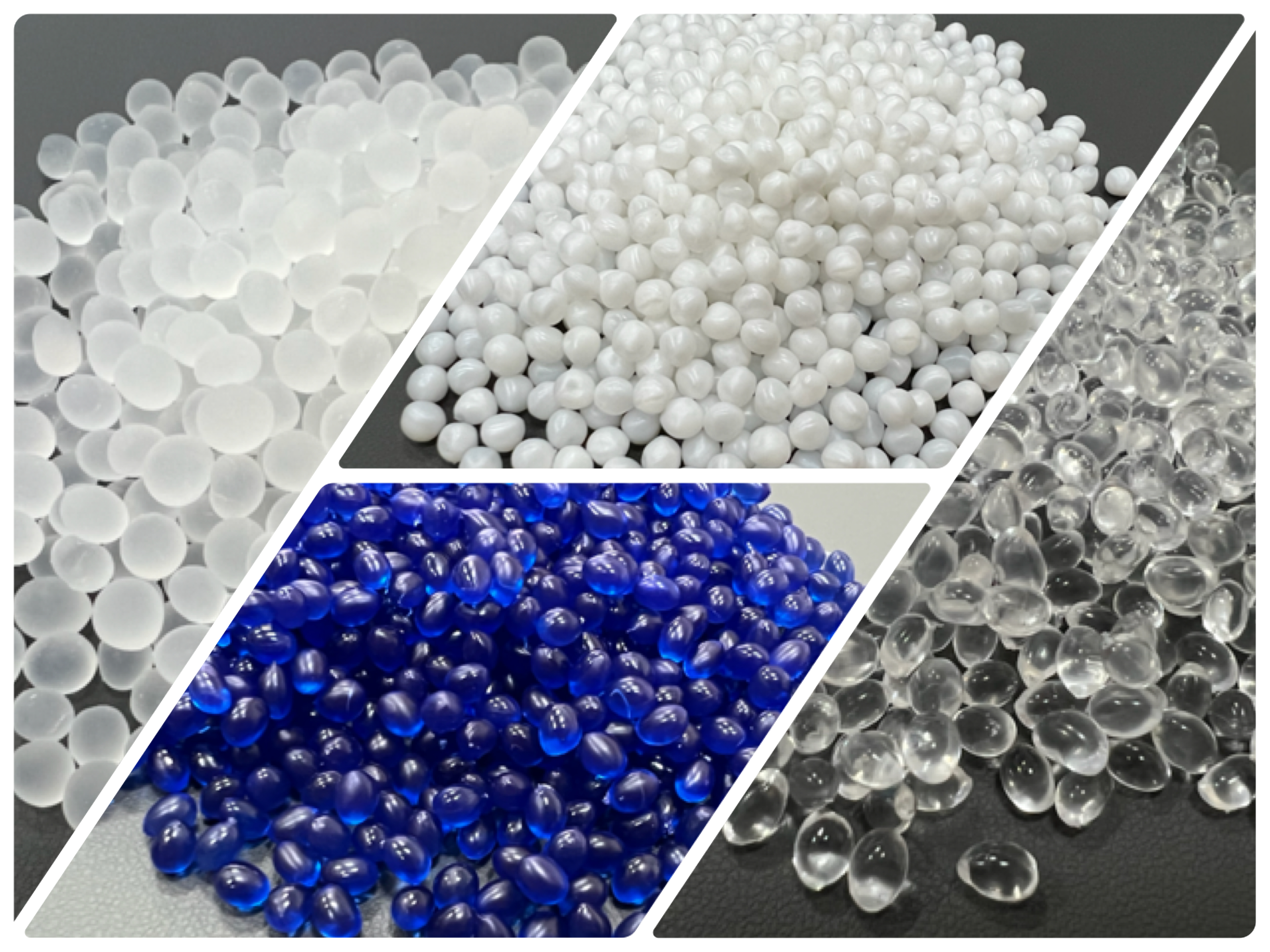

- Exterior : Particles

- Color : Transparent / Translucent/ Natural Color / Black Color / Customized Color

- The optimum combination of materials :HIPS / PS

- Heat distortion temperature :70 ° C

- Cold resistance temperature :-40 ° C

- Material Class is divided into :

W Class: White Color

B Class: Black Color

T Class: Transparent

- Processing Method :Injection, Extrusion

- Storage conditions :At room temperature, avoid direct sunlight, keep away from fire and avoid humid environment.

- Incoterms :FOB,CIF Term...etc.

- Delivery time :7 to 10 working days upon payment.

Shoes, heels, insoles, toys, medical shoes, sporting goods, etc.

Shoe Insole material is soft and fit well in the shoe foundation and can evenly distribute plantar pressure and relieve the discomfort of standing for long time. It can also protect the feet and increase the stability of traveling by foot.

The Heel Counter position, as shown in the image, needs to be soft, supportive and cushioning. This can effectively increase the heel ability to withstand the pressure and friction. This part of the shoe is also known as the heel counter, it is used to stabilize the heel and to shape up the shoes.

| Material Class: W Class:White Color T Class: Transparent |

||||||||

|---|---|---|---|---|---|---|---|---|

| ITEM | TEST METHOD | SERIES | UNIT | |||||

| HR-400W | HR-550W | HR-550T | HR-45D | HR-57D | HR-260UVN-2 | |||

| HARDNESS | ASTM D2240 | 40A | 55A | 55A | 45D | 57D | 60A | SHORE A |

| SPECIFIC GRAVITY | ASTM D792 | 1.05 | 1.05 | 0.88 | 0.99 | 0.99 | 0.92 | G/CM3 |

| ELONGATION | ASTM 412C | 537 | 620 | 580 | 225 | 190 | 420 | % |

| TENSILE STRENGTH | ASTM 412C | 23 | 38 | 36 | 120 | 135 | 60 | KG/CM2 |

| TEAR STRENGTH | ASTM 624C | 16 | 24 | 29 | 70 | 80 | 32 | KG/CM |

| MELT FLOW INDEX | ASTM D1238 | 45E | 60E | 36E | 10E | 9E | 3E | G/10 MIN |

| Melt Flow Index | B:125゚C / 2.16KGS C:150゚C / 2.16KGS E:190゚C / 2.16KGS G:200゚C / 5KGS |

|||||||

| ※ Above information is for reference only. | ||||||||

| GENERAL PROCESSING CONDITIONS | |||||

|---|---|---|---|---|---|

| BARREL TEMPERATURE | REAR | CENTER | FRONT | NOZZLE | MOLD TEMPERATURE |

| 160゚C~177゚C | 166゚C~182゚C | 177゚C~191゚C | 182゚C~204゚C | 16゚C~66゚C | |

| (Mpa) INJECTION PRESSURE | (Mpa) INJECTION PRESSURE |

(Mpa) HOLD PRESSURE |

(Mpa) BACK PRESSURE |

(mm/sec.) INJECTION SPEED | (rpm) SCREW SPEED |

| 34~69 | 14~48 | 0.34~0.69 | 13~25 | 50~70 | |

| ※ Above information is for reference only. | |||||

Shoes

Shoes

Shoe Insole material

Shoe Insole material

medical gear

medical gear

Heel Counter position

Heel Counter position