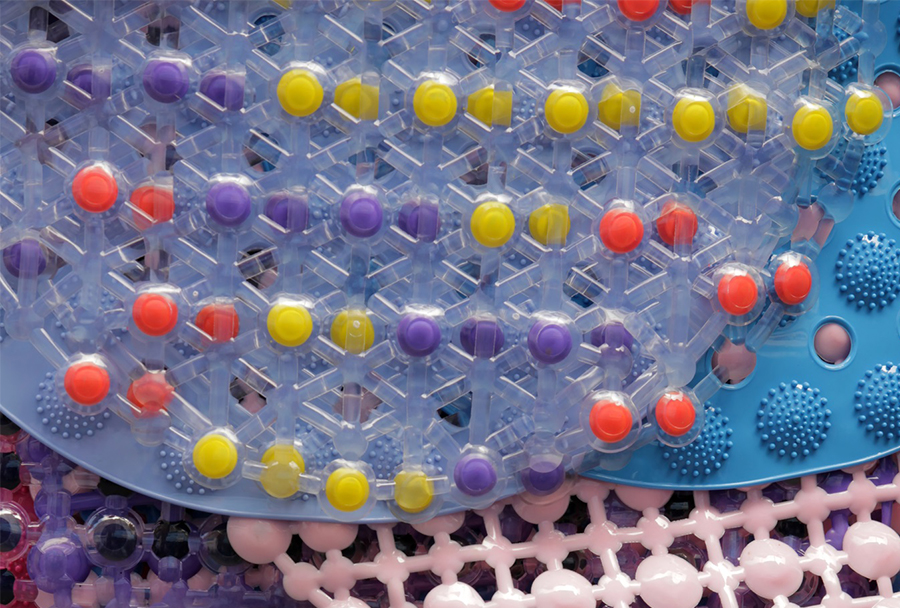

TPE/TPS HG Series(SEBS)

The HG series is used in anti-slip pads/mats, business-type handles and a variety of toothbrushes. For example, the modern toothbrushes are not only becoming more ergonomic in handle grip, but also promoting the comfort and design by TPE/TPS utilization.

Thus, the entire toothbrush looks more "fashionable", in the meantime, the functionality of the toothbrush was breaking the traditional style by using. The TPE /TPS material can be bonded on the grip and back of the brush head, besides, it also can be embedded in and be the bristle. All of which makes cleaning efficient! Thus, the HG series is always to be the best material for toothbrush.

Suitable for most of the thermoplastic processing methods, such as injection molding, extrusion molding and so on.

This material complies with EU RoHS, REACH-SVHC regulations, the Nonyl Phenol Ethoxylates (NPEO), Polynuclear Aromatic Hydrocarbons (PAHs), PFOS / PFOA, Nonylphenol (6P) and other safety tests.

Weather resistant

Aging resistant

Softnes

Combines well with colors

Scratch resistant

Dust resistant

- Hardness : SHORE 20A ~ 63D

- Exterior : Particles

- Color : Natural Color / Black Color / Customized Color

Packing: 25 KGS/ Kraft Bag

- The optimum combination of materials :PP / PE / EVA

- Heat distortion temperature :70° C

- Cold resistance temperature :-40° C

-

○ Anti scratch -

X Non Anti scratch

- Processing Method :Injection, Extrusion

- Storage conditions :At room temperature, avoid direct sunlight, keep away from fire and avoid humid environment.

- Incoterms :FOB,CIF Term...etc.

- Delivery time :7 to 10 working days upon payment.

| Material Class: W Class:White Color B Class:Black Color |

|||||||

|---|---|---|---|---|---|---|---|

| ITEM | TEST METHOD | SERIES | UNIT | ||||

| HG-450 | HG-550 | HG-700 | HG-800 | HG-900 | |||

| HARDNESS | ASTM D2240 | 45A | 55A | 70A | 80A | 90A | SHORE A |

| SPECIFIC GRAVITY | ASTM D792 | 1.05 | 1.05 | 1.05 | 1.05 | 1.05 | G/CM3 |

| ELONGATION | ASTM 412C | 450 | 500 | 420 | 450 | 400 | % |

| TENSILE STRENGTH | ASTM 412C | 17 | 25 | 32 | 45 | 60 | KG/CM2 |

| TEAR STRENGTH | ASTM 624C | 12 | 18 | 25 | 35 | 45 | KG/CM |

| MELT FLOW INDEX | ASTM D1238 | 20E~30E | 20E~30E | 20E~30E | 20E~30E | 20E~30E | G/10 MIN |

| Melt Flow Index | B:125゚C / 2.16KGS C:150゚C / 2.16KGS E:190゚C / 2.16KGS G:200゚C / 5KGS |

||||||

| ※ Above information is for reference only. | |||||||

| GENERAL PROCESSING CONDITIONS | |||||

|---|---|---|---|---|---|

| BARREL TEMPERATURE | REAR | CENTER | FRONT | NOZZLE | MOLD TEMPERATURE |

| 160゚C~177゚C | 166゚C~182゚C | 177゚C~191゚C | 182゚C~204゚C | 16゚C~66゚C | |

| (Mpa) INJECTION PRESSURE | (Mpa) INJECTION PRESSURE |

(Mpa) HOLD PRESSURE |

(Mpa) BACK PRESSURE |

(mm/sec.) INJECTION SPEED | (rpm) SCREW SPEED |

| 34~69 | 14~48 | 0.34~0.69 | 13~25 | 50~70 | |

| ※ Above information is for reference only. | |||||

toothbrushes

toothbrushes

kitchen utensils (ice cube trays, spatulas)

kitchen utensils (ice cube trays, spatulas)

slip mats

slip mats