TPE/TPS H Series(SEBS) - T Class

The material is transparent, and follows with its stretching elasticity, like high permeability, tensile strength, and tear strength. It is environmentally safe and does not cause skin allergies or discomfort.

With a hermetically sealing effect, this material is considerable to utilize in goggles and waterproof liners. Furthermore, the snorkel used to connect the oxygen tubes for diving equipment were also made by this class of material.

Excellent physical properties, with the following features :

Weather resistant

Aging resistant

Softnes

Combines well with colors

Scratch resistant

Dust resistant

Good ductility

Product Specification :

- Hardness : SHORE 5C ~ 90A

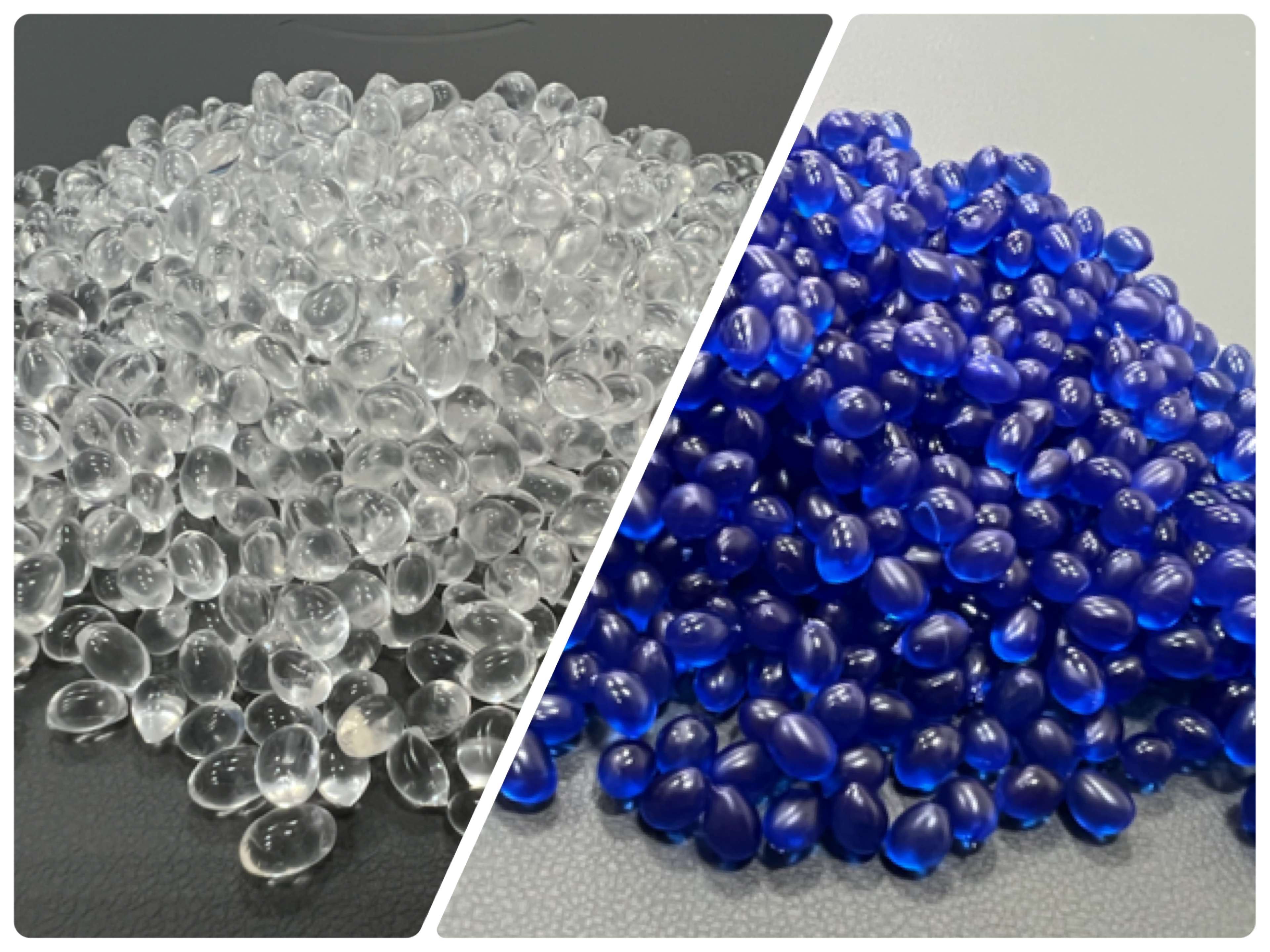

- Exterior : Particles

- Color : Transparent / Customized Color

Packing: 25 KGS/ Kraft Bag

- The optimum combination of materials :PP, PE, EVA

- Heat distortion temperature :70° C

- Cold resistance temperature :-40° C

- Processing Method :Injection, Extrusion

- Storage conditions :At room temperature, avoid direct sunlight, keep away from fire and avoid humid environment.

- Incoterms :FOB,CIF Term...etc.

- Delivery time :7 to 10 working days upon payment.

| Material Class: T Class: White/Black |

||||

|---|---|---|---|---|

| ITEM | TEST METHOD | SERIES | UNIT | |

| H-400T-1 | H-450T-1 | |||

| HARDNESS | ASTM D2240 | 40A | 46A | SHORE A |

| SPECIFIC GRAVITY | ASTM D792 | 0.87 | 0.88 | G/CM3 |

| ELONGATION | ASTM 412C | 610 | 605 | % |

| TENSILE STRENGTH | ASTM 412C | 32 | 40 | KG/CM2 |

| TEAR STRENGTH | ASTM 624C | 20 | 23 | KG/CM |

| MELT FLOW INDEX | ASTM D1238 | 39E | 13E | G/10 MIN |

| Melt Flow Index | B:125゚C / 2.16KGS C:150゚C / 2.16KGS E:190゚C / 2.16KGS G:200゚C / 5KGS |

|||

| ※ Above information is for reference only. | ||||

| GENERAL PROCESSING CONDITIONS | |||||

|---|---|---|---|---|---|

| BARREL TEMPERATURE | REAR | CENTER | FRONT | NOZZLE | MOLD TEMPERATURE |

| 160゚C~177゚C | 166゚C~182゚C | 177゚C~191゚C | 182゚C~204゚C | 16゚C~66゚C | |

| (Mpa) INJECTION PRESSURE | (Mpa) INJECTION PRESSURE |

(Mpa) HOLD PRESSURE |

(Mpa) BACK PRESSURE |

(mm/sec.) INJECTION SPEED | (rpm) SCREW SPEED |

| 34~69 | 14~48 | 0.34~0.69 | 13~25 | 50~70 | |

| ※ Above information is for reference only. | |||||

diving equipment

diving equipment