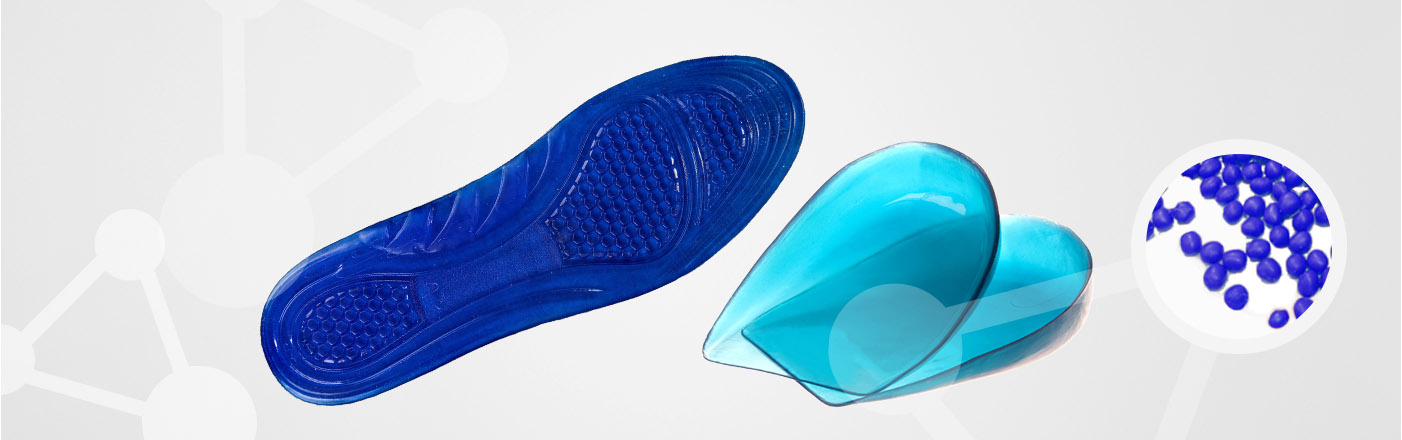

TPE/TPS H Series(SEBS) - C Class

This material is transparent with super soft, which is similar to the texture of skin. Its shockproof effect may reduce the impact of the crash to as touching the ground, particularly with bigger or bouncy actions.

The outstanding shockproof features form the buffer and slow down the uncomfortable feeling by the impact. Since it has first-rate properties, this Class is used a lot in insoles and always becomes the best choice for footwear manufacturers.

Excellent physical properties, with the following features :

Weather resistant

Aging resistant

Softnes

Combines well with colors

Scratch resistant

Dust resistant

Good ductility

Product Specification :

- Hardness : SHORE 5C ~ 90A

- Exterior : Particles

- Color : Transparent

Packing: 25 KGS/ Kraft Bag

- The optimum combination of materials :PP、PE、EVA

- Heat distortion temperature :70° C

- Cold resistance temperature :-40° C

- Processing Method :Injection, Extrusion

- Storage conditions :Injection, Extrusion

- Incoterms :FOB,CIF Term...etc.

- Delivery time :7 to 10 working days upon payment.

| Material Class: C Class:Extra-Soft |

|||||

|---|---|---|---|---|---|

| ITEM | TEST METHOD | SERIES | UNIT | ||

| H-115C | H-120C | H-130C | |||

| HARDNESS | ASTM D2240 | 9C | 15C | 23C | SHORE C |

| SPECIFIC GRAVITY | ASTM D792 | 0.88 | 0.88 | 0.88 | G/CM3 |

| ELONGATION | ASTM 412C | 1200 | 1100 | 1100 | % |

| TENSILE STRENGTH | ASTM 412C | 6 | 10 | 12 | KG/CM2 |

| TEAR STRENGTH | ASTM 624C | 3 | 6 | 10 | KG/CM |

| MELT FLOW INDEX | ASTM D1238 | 20B | 12B | 10B | G/10 MIN |

| Melt Flow Index | B:125゚C / 2.16KGS C:150゚C / 2.16KGS E:190゚C / 2.16KGS G:200゚C / 5KGS |

||||

| ※ Above information is for reference only. | |||||

| GENERAL PROCESSING CONDITIONS | |||||

|---|---|---|---|---|---|

| BARREL TEMPERATURE | REAR | CENTER | FRONT | NOZZLE | MOLD TEMPERATURE |

| 160゚C~177゚C | 166゚C~182゚C | 177゚C~191゚C | 182゚C~204゚C | 16゚C~66゚C | |

| (Mpa) INJECTION PRESSURE | (Mpa) INJECTION PRESSURE |

(Mpa) HOLD PRESSURE |

(Mpa) BACK PRESSURE |

(mm/sec.) INJECTION SPEED | (rpm) SCREW SPEED |

| 34~69 | 14~48 | 0.34~0.69 | 13~25 | 50~70 | |

| ※ Above information is for reference only. | |||||

rehabilitation ball、fitness equipment

rehabilitation ball、fitness equipment